The Ebbco Closed Loop Filtration System

Is designed to filter and treat waterjet overflow water for reuse. This system can service single or multiple heads on any waterjet table. By using the Ebbco Closed Loop System you will eliminate the need to go to drain by recycling the water, Reduce your water consumption, your costs for treated water such as RO units or water softeners, the machines maintenance and maximize the performance but most importantly, The Ebbco closed loop system protects your high pressure pump by always supplying the manufactures specified water quality.

Is designed to filter and treat waterjet overflow water for reuse. This system can service single or multiple heads on any waterjet table. By using the Ebbco Closed Loop System you will eliminate the need to go to drain by recycling the water, Reduce your water consumption, your costs for treated water such as RO units or water softeners, the machines maintenance and maximize the performance but most importantly, The Ebbco closed loop system protects your high pressure pump by always supplying the manufactures specified water quality.

How it Works

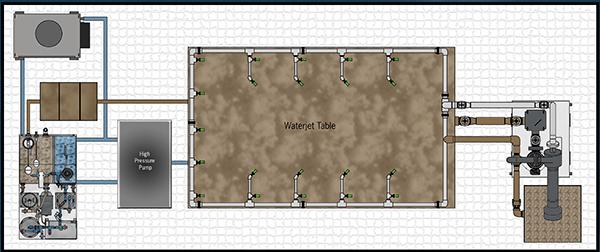

The Waterjet table overflows into a seting weir where sludge is settled out before entering the filtration system. Water enters the dirty side of the Stainless Steel Reservoir on the filtration system, the filter pump send the water first through a Stainless Steel Bag Vessel containing a 1 micron filter bag, then a Stainless Steel Ebbco Hurricane Filter Vessel containing a 0.35 Micron Filter Cartridge. The clean water is then sent through a chiller or heat exchanger, to remove the heat from the machining process. Water if necessary, enters the Stainless Steel DI Resin Vessel containing a special blend of resin specifically designed for waterjet applications, where dissolved solids are removed, maintaining the manufacturers pump specified water quality. Finally the water enters the clean side of the systems reservoir. An ozone generator is installed inside the clean tank for bacteria control. Clean, treated water is then sent by a clean delivery pump through a 0.35 micron final filter to the high pressure pump.

Benefits

Eliminate the Drain Completely

By recycling the water no dissolved solids are sent down the drain.

Reduce Water Consumption up to 90% of Normal Usage.

By Reusing your overflow water you reduce your water and sewage bills drastically.

Reduce the Requirement for Make up Water Treatments

The Ebbco Closed Loop System uses a small amount of water and treats it before going to the high‐pressure pump.

Maximize Orifice Life

By reducing machine maintenance and maximizing the machine performance. Protect you High‐Pressure Pump ‐‐ ALWAYS supplies the manufacture

System Features

Closed Loop for Multiple Heads

The Ebbco Closed Loop Filtration System for multiple cutting heads is designed to filter up to 4 gpm, System incorporates Dual Bag Vessel, Dual Hurricane Filter Vessels and Dual DI resin Vessels and a 200 gallon reservoir for larger holding capacity.

Chillers

Chillers are designed to cool the OEM’s high pressure pumps as well as the Ebbco Closed Loop Filtration system, providing cooled DI treated water for cuting purposes to maximize high pressure pump seal life. We offer various models such as Closed Loop Chillers, In‐Line Chillers and Flow‐Thru Chillers, to work with all Waterjet manufactures high pressure pumps.

Settling Weir

The Ebbco over‐under settling weir system provides maximum settling time for removal of suspended solids. The Ebbco settling weir is fitted with a disposable liner for easy change out. The liner is capable of holding up to 9 cu.ft. of abrasive. The Settling Weir has a compact foot print of 2’ x 3’ 10 Gauge Steel with an rust Inhibiting Epoxy Finish. The Settling Wire has proven to lengthen filter life.

Reverse Osmosis

The Ebbco Reverse Osmosis system is used to lower the operating costs of the Ebbco Closed Loop System in applications where make‐up water quality is poor. Reverse Osmosis Systems are typically recommended when make up water is greater than 250 ppm total dissolved solids.