The Ebbco Abrasive Removal System

For Waterjet Cutters

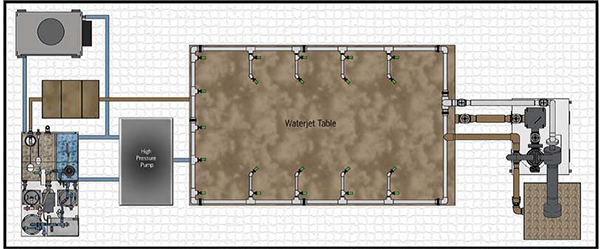

Ebbco’s Abrasive Removal System is designed to continuously remove exhausted abrasive that collects in the Waterjet catch tank, thus eliminating downtime for cleanout and maximizes production. The Abrasive Removal System can be adapted to any Abrasive Waterjet Cuting Machine. The Selection of an Ebbco Abrasive Removal System is based on the square footage of the Waterjet Catch tank and number of cuting heads. Ebbco engineers design a custom fit sweeper package to move large quantities of Abrasive laden along the bottom of the tank, toward the suction. Thus, maximizing your productivity and eliminating down time for tank cleaning. The Ebbco Abrasive Removal’s Pump carries a one‐year or 2000 hour warranty. By using the Abrasive Removal Along with a Closed Loop Filtration System will reduce the consumable costs.

Ebbco’s Abrasive Removal System is designed to continuously remove exhausted abrasive that collects in the Waterjet catch tank, thus eliminating downtime for cleanout and maximizes production. The Abrasive Removal System can be adapted to any Abrasive Waterjet Cuting Machine. The Selection of an Ebbco Abrasive Removal System is based on the square footage of the Waterjet Catch tank and number of cuting heads. Ebbco engineers design a custom fit sweeper package to move large quantities of Abrasive laden along the bottom of the tank, toward the suction. Thus, maximizing your productivity and eliminating down time for tank cleaning. The Ebbco Abrasive Removal’s Pump carries a one‐year or 2000 hour warranty. By using the Abrasive Removal Along with a Closed Loop Filtration System will reduce the consumable costs.

How it Works

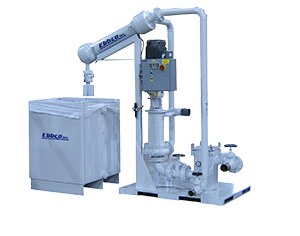

A specifically engineered PVC sweeper package is placed inside the waterjet catch tank, this eductor package is designed to keep the abrasive in suspension and pushed toward the pump suction. A Heavy‐Duty Closed Column Pump pulls the abrasive laden water from the catch tank and send it first through a strainer basket to collect all large particles before entering the pump, Water is then sent through a centrifugal separator where solids are spun out and collect inside the collection chamber where the solids are purged into a hopper with a removable liner. Clean fluid then exits the top of the separator and is pushed back to the waterjet through the eductor packaged where the process continues.

Benefits

Maximizes Productivity

By eliminating down time for catch tank cleaning.

Reduces the Possibility of Thermal Distortion‐

By removing the abrasive from the table, heat from the machining process is dissipated.

Reduces Closed Loop Consumable Costs

By removing the abrasive the filtration system can concentrate of treating the water rather than removing the abrasive.

System Selection

Selection of an Abrasive Removal System is based on square footage of the Water‐Jet catcher tank and number of cuting heads. Catcher tanks are unique and may contain obstacles such as support stanchions and bladders. Ebbco engineers will design a sweeper package to specifically fit your catch tank. The Ebbco sales/engineer department will be happy to assist you in recommending the proper Abrasive Removal System that will best fit your application.

System Features

Sweeper Package Installation

A Sweeper Package is specifically designed to fit the catcher tank and can be installed by a qualified Ebbco service technician. The sweeper package incorporates multiple eductors with a 4:1 ratio. The eductors enhance water flow and keeps the abrasive in suspension, pushing it toward the system suction port.

System Purge

Abrasive is purged from the system constantly. As the Water‐Jet deposits abrasive into the catcher tank, the Ebbco Abrasive Removal System removes it. Spent abrasive is deposited into the same 4400lb bag that the abrasive was purchased in..

Abrasive Disposal

Spent abrasive is deposited in the 4400 lb bag at the same rate at which it enters the catcher tank. The spent abrasive is relatively clean and void of parts larger than 1/8” diameter. The Spent abrasive bag is lifted from the disposal hopper and disposed of in a manageable 4400 lb bag.